Why Did My Plug Stop Working?

What a loaded question! There can be many reasons why your receptacle stopped working, such as the device is worn out or damaged, a rodent chewed through the wire, it’s a GFCI plug which needs to be reset, or maybe the breaker tripped.

One of the main reasons we see is that the device was ‘backstabbed’ rather than mounted around the screw on the side of the device. This is particularly common in subdivisions. So what does it mean?

Every switch and receptacle has side screws that are meant to have the wire ends curled around them and then fastened down by the screw. However, in the back of these devices the manufacturer also installs little holes where the wire ends can be pushed into and then be tightened with the side screws. But why is this an inferior connection? After about 4-5 years, the mechanical motion of push and pull (plugging in and unplugging your device) loosens the wire connections in the back until the wire end either pulls out or eventually arks/melts off. The latter will also cause the sensitive arc fault breakers to trip, which can be a real nuisance.

Backstabbed plug – the once white wire has a burnt, damaged jacket, showing corrosion and the receptacle has fallen out.

Now imagine twisting the wire around a screw instead. Without even tightening the screw, you can tug on the wire and it will not come loose. This is the long lasting solution, keeping your devices operable and avoiding breaker tripping. Why would anybody rather backstab than install it around the screw? Speed, of course! It’s much faster to backstab, which is why we see it so often in subdivisions, but it’s also against electrical code.

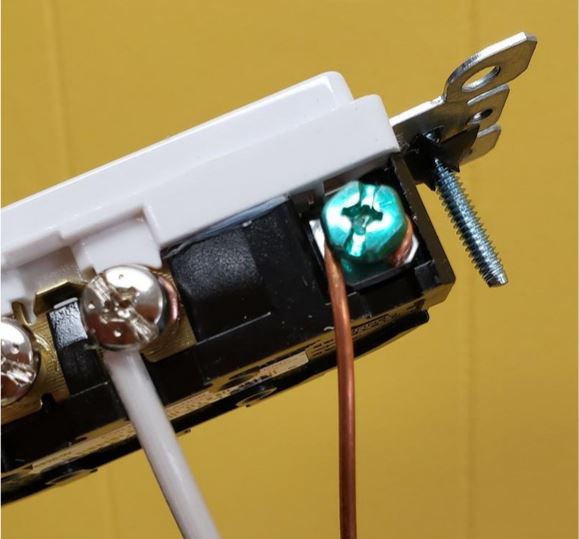

This receptacle has wire turned around the screw. Even though the screw has not been tightened, the wire is not falling off, hence, a lasting and safe connection.

So what should you do if you know that your devices (especially receptacles) have been backstabbed? To save you many future service calls, we recommend having all affected devices replaced at once. The constant overheating makes wires very brittle, and we often find receptacles that have the wires melted into the back slots but are still miraculously working until one day the wire breaks right off.

At Amp Champ, we like to go one step further. We tape off the side screws with electrical tape to prevent any corrosion. Additionally, this provides an extra layer of shock hazard safety if a non-electrician handles the devices. When you work with Amp Champ, you can trust that we always have your safety, security, and comfort in mind!

Related Posts

What to Look for When Buying New Light Fixtures

With the rise in popularity of online shopping, along with the ease of accessibility offered by global houseware brands

Why We Only Do In Person Quotes

Would you ever buy a new house without touring it first? What about online shopping–would you ever purchase items before seeing photos?

DIY Home Electrical Inspection

It’s spring in South Georgian Bay, and it’s the perfect time to ensure all of your home’s electrical needs are well taken care of